Cooling towers are vital across many industries, ensuring effective heat dissipation and maintaining operational efficiency. Recently, a study by Hashemi et al. has shed light on the latest advancements in fill media technology for wet cooling towers, highlighting significant improvements in performance.

Key Findings

Fill media are integral to the efficiency of wet cooling towers, facilitating the exchange of heat and mass between water and air. The study highlights that innovations in fill media materials and configurations can enhance cooling efficiency dramatically. New fill media designs have been shown to improve the cooling range, effectiveness, and Merkel number by 28%, 85%, and 131%, respectively. These improvements can lead to greater energy efficiency and reduced operational costs for industries relying on cooling towers.

Types of Cooling Towers

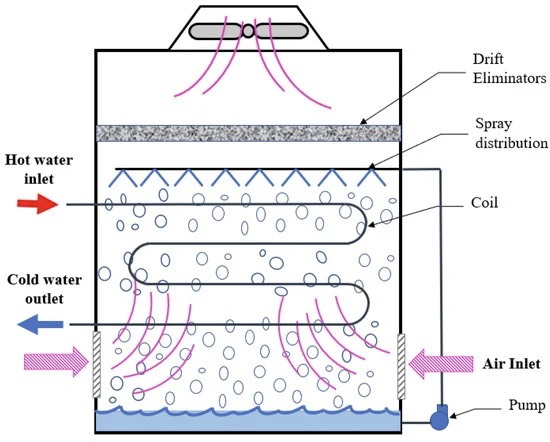

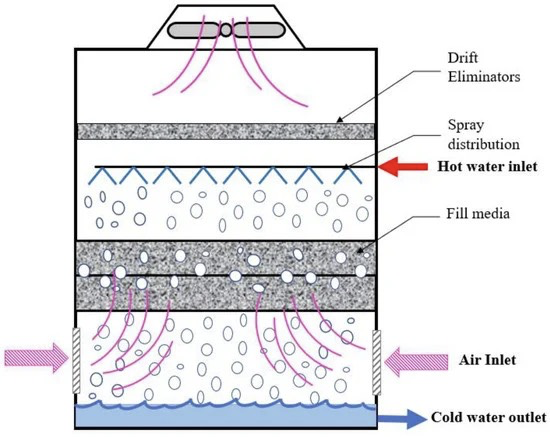

There are two main types of cooling towers: open (or direct-contact) and closed-circuit (or indirect-contact). Open cooling towers allow water to come into direct contact with air, promoting evaporation and cooling. Closed-circuit towers, on the other hand, separate the water from the air using a heat exchanger. Both types have their specific applications and advantages, with open towers being more efficient in terms of cooling but consuming more water.

Role of Fill Media

Fill media are designed to maximize the contact area between water and air, enhancing the efficiency of heat and mass transfer. These components are typically made from materials like plastic, metal, or wood, chosen for their low thermal conductivity and cost-effectiveness. The structure of fill media provides a large surface area, allowing for effective heat exchange without significantly increasing the volume of the cooling tower.

Technological Advancements

Recent advancements in fill media technology focus on improving the design and material properties to boost heat transfer efficiency. Novel geometries and advanced materials have been incorporated to optimize performance. These innovations are crucial for industries aiming to achieve better cooling efficiency, lower energy consumption, and enhanced sustainability.

Impact on Industry

The insights from this study are invaluable for engineers and designers working on cooling tower projects. By understanding the effects of different fill media, they can make informed decisions to optimize cooling tower performance. This not only ensures efficient heat dissipation but also supports broader goals of energy efficiency and environmental sustainability.

In conclusion, the continuous improvement in fill media technology is pivotal for the future of cooling tower efficiency. As industries strive for greater sustainability and operational excellence, these advancements will play a key role in achieving those objectives.